Features and Benefits

Fire Resistant

Class "A" 30-min extended fire rating

(available up to 1-hour)

Water Resistant

Non-porous therefore

impervious to pests, water & wind

High strength to

weight ratio

Pound-for-pound stronger than steel.

and weighs 75-80% less

Ballistic Rating

UL 752 Level 1 ballistic rated

0.25" EXOSHELL Panel

(available up to level 8 and 50 caliber)

Hurricane Resistant

Approved for use in exposure "D" high-velocity hurricane zone (hvhz) regions

Impact Resistant

Impact rated up to 250 MPH

Energy Efficient

Materials with Zero heat TRANSFER

mean Superior thermal performance

(up to R42 available).

Mold & Corrosion

Resistant

Resistant to mold, corrosion and

chemical degradation.

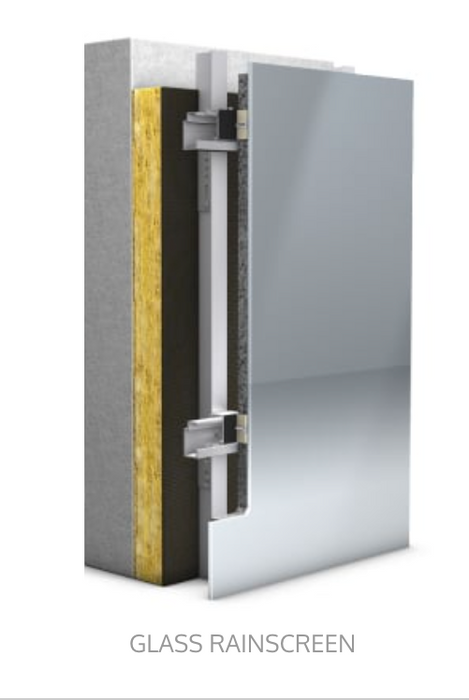

EXOSHELL

RAINSCREEN SYSTEMS

What is EXOSHELL

For decades we’ve been building walls from thermally conductive materials like steel or aluminum and then adding insulation or isolating the layers to reduce the thermal bridging through those walls. Eliminating layers dramatically reduces cost.

New technologies utilizing fiberglass composites are changing the way we build. Starting with low thermal conductivity materials improves energy performance while reducing embodied (CO2 ).

Pre-fabricated panels are built in our factory and shipped to site ready for installation. Fast enclosure time protects your building, lowers cost, improves quality, durability and performance.

EXOSHELL is a 8th generation wall system consisting of a single layer of composite ballistic armor plate bonded to a pultruded composite frame assembly, which is factory fitted, sealed, and fire coated providing zero water penetration and zero air permeability. Suitable for all cladding types.

EXOSHELL

Performance Characteristics

-

Florida Product Approval # FL 36888 for use in HVHZ Exposure “D”

-

Structural Performance (ASTM E330)

-

Missile Impact up to 250 mph (ICC 500; TAS 201, 202, 203)

-

Air & Water Tightness (ASTM E330, E331, E2357)

-

Performance in Fire (NFPA 285, NFPA 268, ASTM E119, E84, E2768)

-

Seismic Racking and Shear (ASTM E72)

-

ICC-ESL-1624

-

8th Edition (2023) Florida Building Code Compliant

-

Thermal Performance (minimal thermal bridging)

-

ICC ESL-1624 ICC ESL-1624

Thermal Performance

-

U-0.048 [R-19.1 Effective with no (ci)]

-

U-0.036 [R-28.0 Effective with 2” (ci)]

Northstar is committed to full material transparency. Our HPD outlines product contents and associated health information, ensuring safer building materials for both occupants and installers.

Through LCA studies, we measure the full environmental footprint of our products, from raw materials to end-of-life — providing data-driven insights to reduce impact.

The EPD quantifies our product’s environmental performance, making it easier for project teams to evaluate sustainability metrics and align with green building standards.

Northstar products are being evaluated under the DECLARE™ program, often referred to as a “nutrition label” for building materials. This transparent labeling supports healthier, low-toxicity construction.

Our products contribute toward LEED™ certification credits by disclosing and optimizing material ingredients, supporting project teams in achieving higher green building ratings.

By using fiber reinforced polymer (FRP) composites, Northstar reduces embodied carbon compared to steel, helping project owners lower emissions and meet carbon reduction goals without sacrificing strength or performance.

Sustainability

Partners with

Formerly Interra Facades, Mödfacade works throughout North America with modern, durable facade solutions- connecting innovative products with progressive designers.

Not long ago we designed and built buildings that were "energy hogs" with little regard for their impact on the environment or CO2 emissions.

Today's standards require new approaches to achieve performance and aesthetic objectives.

.jpg)

EXOSHELL

Curtain Wall Systems

PROVEN COMPOSITE MATERIALS

EXOSHELL utilizes materials and processes long-proven in the aerospace, marine and automotive industries. Fiber Reinforced Polymer (FRP) composites are widely known to be strong, lightweight and corrosion resistant.

EFFICIENT DIGITAL MANUACTURING

Custom digital modeling is core to the EXOSHELL manufacturing process. Your CAD or Revit model is refined by our engineering team, then converted into digital output files that are uploaded to automated CNC machines which produce the components.

NFPA 285 COMPLIANT

EXOSHELL is the only NFPA 285-compliant FRP curtain wall system available today. Leveraging our fire coating process and our Florida Product Approval, EXOSHELL can be used on any building, including those up to 500 feet tall in Exposure "D" High Velocity Hurricane Zone

(HVHZ) regions.